Read on to learn all about engineered wood flooring: how to choose the best engineered wood flooring products, and why and where you should consider installing it.

Best Engineered Wood Flooring: Heritage Mill Oak Harvest Engineered Click Hardwood, Bellawood Red Oak Engineered Hardwood Flooring, Bellawood Artisan Manhattan Chevron, Malibu Wide Plank French Oak Rincon Hardwood Flooring, Malibu Wide-Plank Maple Cardiff, Bellawood Select Maple Engineered Hardwood Flooring…

Please read on for more detailed information.

Best Engineered Hardwood Flooring

Here are the top picks for some of the best engineered wood flooring across a variety of categories, based on the aforementioned shopping considerations.

Best Overall: Heritage Mill Oak Harvest Engineered Click Hardwood

Check out Heritage Mill’s Oak Harvest Engineered Click Hardwood Flooring if you’re a DIYer looking for a high-quality click-style engineered wood floor. This flooring is 4¼ inches wide and 3/8 inches thick, and it is available in a variety of lengths to mimic real wood floors.

The veneer layer of this flooring is prefinished oak that’s 2 millimeters thick. To make sure the veneer’s surface is as durable as possible, a protective layer of aluminum oxide has been applied. The core layer is made up of five solid wood layers that were glued together for stability with the grain running perpendicular to each other. Twenty square feet of floor are covered by one case.

Red oak, tan, natural, and oak are just a few of the more than 4 finish options available for this flooring. Installation requires a lay-and-click floating design, though gluing is also an option.

Runner Up: Bellawood Red Oak Engineered Hardwood Flooring

Red oak veneer that is 3 millimeters thick is what gives Bellawood’s Red Oak Engineered Hardwood Flooring the classic appearance of solid hardwood floors. One of the most common options is oak, which serves as the industry standard for wood hardness. This engineered oak flooring is more resistant to scratches, stains, and scuffs than solid oak flooring because of a protective layer of aluminum oxide on the veneer.

Over a plywood core that resists changes in humidity and moisture is the oak veneer. To mimic the irregular lengths of solid hardwood flooring, each plank is 5 inches wide, ½-inch thick, and comes in random lengths between 12 inches and 71½ inches. Although this product has a tongue-and-groove design, installation calls for either nailing or gluing.

Suggested reading: Types of flooring you can put over ceramic tile includes ceramic tiles, laminate flooring, vinyl flooring, carpet, epoxy coating, cork flooring, wood flooring, and new fired tile. But, why choose these floorings? Below will give specific reasons.

Splurge: Bellawood Artisan Manhattan Chevron

If you have the money, the stylish chevron pattern and 11-1/2-inch width of Bellawood Artisan Manhattan Chevron could turn your home’s flooring into a modern masterpiece.

A 100-year residential warranty is provided by the manufacturer and is transferrable between owners. But this flooring’s finish cannot be sanded and refinished, and installing the patterned design correctly could be difficult for do-it-yourselfers. Read more: Can You Refinish Engineered Hardwood Floors?

Best Value: Malibu Wide Plank French Oak Rincon Hardwood Flooring

This Malibu Wide Plank product is a desirable choice for DIYers looking to save money by installing engineered wood flooring. This oak flooring has planks that are 6½ inches wide, which will give a space a high-end appearance at an affordable price. This floor’s thin 1.2 millimeter oak veneers cannot be refinished because of their thickness. The veneer, however, is protected by a hard aluminum oxide coating that will fend off scuffs, stains, and scratches that would necessitate refinishing. For a thinner veneer, that coating is crucial.

Each plank in this kit is 47½ inches long and 3/8 inches thick. Since all of the boards are the same length, the floor won’t appear random like flooring with random-sized boards would. This floor can be glued down by installers if they so choose, but it is made to click together and float without any problems.

Extra-Wide Planks: Malibu Wide-Plank Maple Cardiff

The Malibu Wide-Plank Maple Cardiff is a fantastic option for those who prefer a modern appearance and is 7-1/2 inches wide. It has a thick, seven-ply plywood core and eight different color options for added stability.

Due to the tongue-and-groove edges that can be glued, floated, or stapled, installation is fairly straightforward. One of the best warranties available is the lifetime limited residential warranty.Read more: How to Install Engineered Hardwood

Upgrade Pick: Bellawood Select Maple Engineered Hardwood Flooring

The Select Maple Engineered Hardwood Flooring from Bellawood features premium, three millimeter-thick creamy maple veneers. Because it can be refinished, this product has a lifespan and durability that rival solid hardwood flooring. Adding to the veneer’s durability is a solid plywood core that is ½ inch thick.

The planks are 5 inches wide, making this product a good choice for people who want a posh farmhouse-style interior. The installed floor will have the haphazard appearance of solid wood because the lengths range from 12 inches to 71.5 inches. A top-of-the-line, patented finish that resists scratches is applied to the floor. The tongue-and-groove floor from Bellawood needs to be installed with glue or nails.

Water Resistant: AquaSeal Moselle River Maple

Thanks to an SPC core that provides water protection for up to 72 hours, AquaSeal Moselle River Maple works for those who anticipate frequent spills and splashes from kids, pets, and other family members. This water resistance is also protected by an impressive 50-year residential warranty, so even if you don’t notice a spill or it occurs overnight, your floor won’t be damaged.

Extra-Thick Plank: Aspen Flooring Euro White Oak

With a veneer that is an impressive 4-mm thick, Aspen Flooring Euro White Oak is a great choice for homes with high traffic. This extra-thick veneer can be sanded and refinished several times, great for those who want their floors to last an extremely long time. Additionally, it comes in 28 finishes, so irrespective of the current design of your home, you should be able to find a solution.

It may be more expensive than our other picks, but the durability and refinishing options could be worth it to the right customer.

Best Wide Plank: Bellawood Willow Manor Oak Engineered Hardwood

Willow Manor Oak engineered wood flooring from Bellawood provides the wide plank floors that certain spaces and design motifs demand. These 7-inch-wide, ½-inch-thick flooring planks give a room a rustic, unpolished appearance. Bellawood Willow Manor Oak offers longer-than-average lengths ranging from 16 inches to 84 inches in addition to wide planks. This gives the flooring a rough appearance that is perfect for spaces where you want a farmhouse or old-world style.

This flooring has a plywood core and a veneer layer of 3-millimeter white oak that can be refinished. A veneer’s character comes from variations in its color, grain, and knots. Furthermore, the clear aluminum oxide finish adds durability and scratch and scuff resistance. Gluing or nailing is necessary for installation.

Narrow Plank: Bruce Oak Gunstock

When going for a traditional look, Bruce Oak Gunstock’s three-inch width works well in compact spaces. With a strong HDF core that is resistant to moisture damage, it is also tough. Future repairs are possible thanks to a veneer thickness of 1.8 mm. But remember that its 25-year limited warranty is a bit shorter than most other choices.

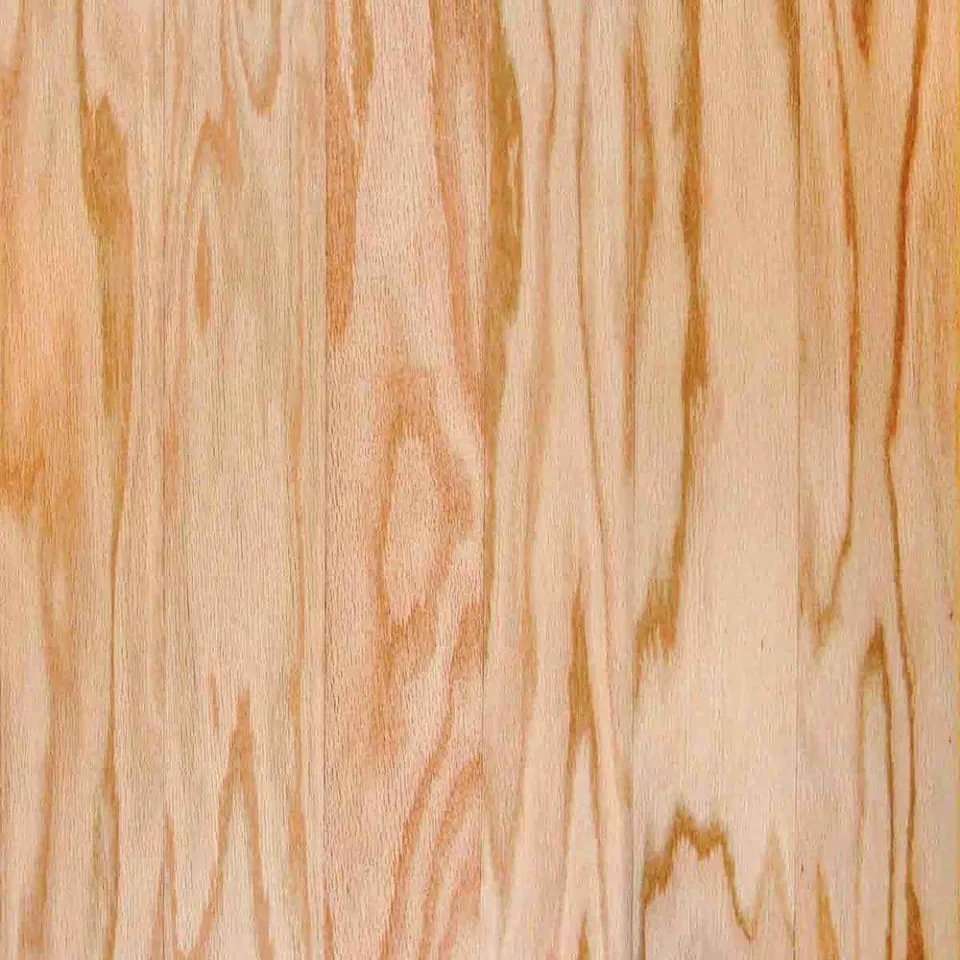

Best traditional: Heritage Mill Red Oak Natural Engineered Hardwood

Heritage Mill’s Red Oak Natural flooring comes in 4¼-inch-wide planks that are a good pick for rooms where you want a more modern look. The veneers are made of real domestic oak hardwood that’s 2 millimeters thick with a clear finish of aluminum oxide for protection. The veneer sits atop five layers of solid wood, so this is a durable pick.

The 3/8-inch thick planks are available in a variety of lengths. However, the tongue-and-groove click design will enable quicker, glueless installations even though DIYers can glue this product down.

Types of Engineered Wood Flooring

There are many types of engineered wood flooring. It can be categorized based on the installation method, surface finish, texture, pressure used during production, and even the type of wood. The installation method is the most fundamental and crucial classification to take into account because it will further reduce your option pool.

Adhesive Installation Method

This method involves adhesive to be applied on joints to maximize the grip. Whether pre-glued or glued during installation, the adhesive installation method glues the planks onto the subfloor. The adhesive method is often used to install engineered wood floors to concrete subfloors.

Nail-Down Installation Method

Although it is less common than other installation techniques, nail-down installations can help fasten engineered wood floors to wooden subfloors. In this instance, the engineered wood planks are fastened to the subfloor with nails.

Click-Lock Installation Method

The click-lock installation technique is used for contemporary engineered wood flooring options. By snapping the tongue-and-groove planks together, this produces a floating floor. The click-lock method is also the most cost-effective option because no nails or glue are required.

The flooring is supported by a subfloor and is supported by its weight. The ability to quickly remove the flooring for repairs or replacement is another advantage of this installation technique. Additionally, many click-lock engineered wood floor planks are simple for enthusiastic do-it-yourselfers to install.

Engineered Wood Flooring Shopping Tips

When shopping for engineered wood floors, there are a few things to keep in mind. Keep in mind these suggestions when purchasing engineered wood flooring planks from different suppliers because not all of them are created equal.

Get Samples of Different Styles

Engineered wood floors are mass-produced. Even if you order flooring from the same manufacturer, mass production methods can result in planks with varying widths, lengths and thicknesses, which can make installation more complicated. Samples allow you to compare options and visualize how various thicknesses, colors, and finishes might appear in your home, which can help you narrow down your selection.

Verify Width and Lengths on Any Quotes

Three inches wide and roughly three feet long describe the typical engineered wood floor plank. Nevertheless, a few suppliers can provide planks that are six to ten inches wide. Check and confirm the width and length of your planks on every quote you receive as you shop for engineered wood flooring. Don’t rely on word-of-mouth specification details because getting the wrong width may require you to buy additional planks to finish the project.

Ask for the Manufacturing Method

One of the reasons to select engineered wood floors, in addition to their many advantages, is their aesthetic appeal. Each engineered wood flooring plank’s veneer layer gives it its final appearance, and there are two ways to do this: by using a dry saw cut with a saw blade or a rotary peel with a knife blade.

They both produce aesthetic qualities that are different from one another. The dry saw will give the impression of a solid wood floor. The sliced and rotary peel material, on the other hand, has a veneer that is thinner and won’t last as long as the other. Once more, this explains why getting samples is so crucial during the purchasing process.

See more:

Things to Consider Before Purchasing Engineered Wood Flooring

Consider the following before making any final purchase:

- Always look for a thicker veneer to ensure your floors last longer. Your floors won’t be able to be refinished or sanded if the veneer layer is too thin; once they become worn out, they will need to be replaced.

- A high-quality plywood center is a must for engineered wood flooring. More so than solid wood flooring, engineered wood floors can withstand changes in temperature and humidity. Look for engineered wood floors made with a more flexible plywood core for the best results.

- Your engineered wood floor will be more resilient if it has more finish layers. The engineered wood flooring you want should have between three and nine layers in addition to a plywood core. The durability of the product increases with layer count.

- Seek out options with extra features. Not all engineered wood floors share the same characteristics. Choose a product that fits your needs and way of life. For instance, homes with kids and pets may favor waterproof and scratch-resistant planks. Other features include prefinished, stainable, and dent-resistant.

FAQs

Do You Need to Seal Engineered Wood Flooring?

Most engineered wood floors come pre-finished. Even so, sealing it is a good idea to give your flooring an extra layer of defense against stains, dings, and general wear and tear.

Is Engineered Wood Eco-friendly?

Because each plank uses less wood than a traditional hardwood floor, it is more environmentally friendly than that style. Because fewer trees were cut down to create the floor, more lumber was able to be harvested.

How Do You Tell If You Have Engineered Hardwood?

You can tell engineered hardwood flooring from solid hardwood by looking at the sides because it typically floats over the subfloor. Pick up a loose plank and check the sides. You have hardwood if it is one continuous piece of wood. It’s most likely engineered wood if there are multiple layers of wood present.

How Long Does Engineered Wood Flooring Last?

An investment that will typically pay off after 20 to 30 years is a premium engineered wood floor. Avoid products without a UV-protective finish layer and those with a veneer layer that is thinner than 2mm if you want your engineered wood floors to last as long as possible.

What is the Best Thickness for Engineered Wood Flooring?

Working with engineered wood floors gives you access to a wide variety of veneer thicknesses. However, since engineered wood flooring cannot be refinished, you should search for one with a thicker veneer that permits sanding. Ideally, you want a veneer layer of at least 3mm to allow for it to be sanded at least twice after installation.

Does Engineered Wood Flooring Scratch Easily?

Engineered wood floors scratch similarly to solid hardwood floors. But compared to solid hardwood, engineered wood flooring has a higher scratch resistance rating.

Summary: Best Engineered Hardwood Flooring

For a reliable, durable engineered flooring option, consider the Heritage Mill hardwood flooring with its aluminum oxide protective layer, easy installation, and multiple finish options. Or, for a more affordable option, consider the moisture-resistant Bellawood Red Oak flooring, which also has irregularly sized planks for a more authentic appearance.

If you have any questions, please leave a comment. My Prime Home tries to give you the best home improvement information. Don’t forget to share the post. Thank you for reading.